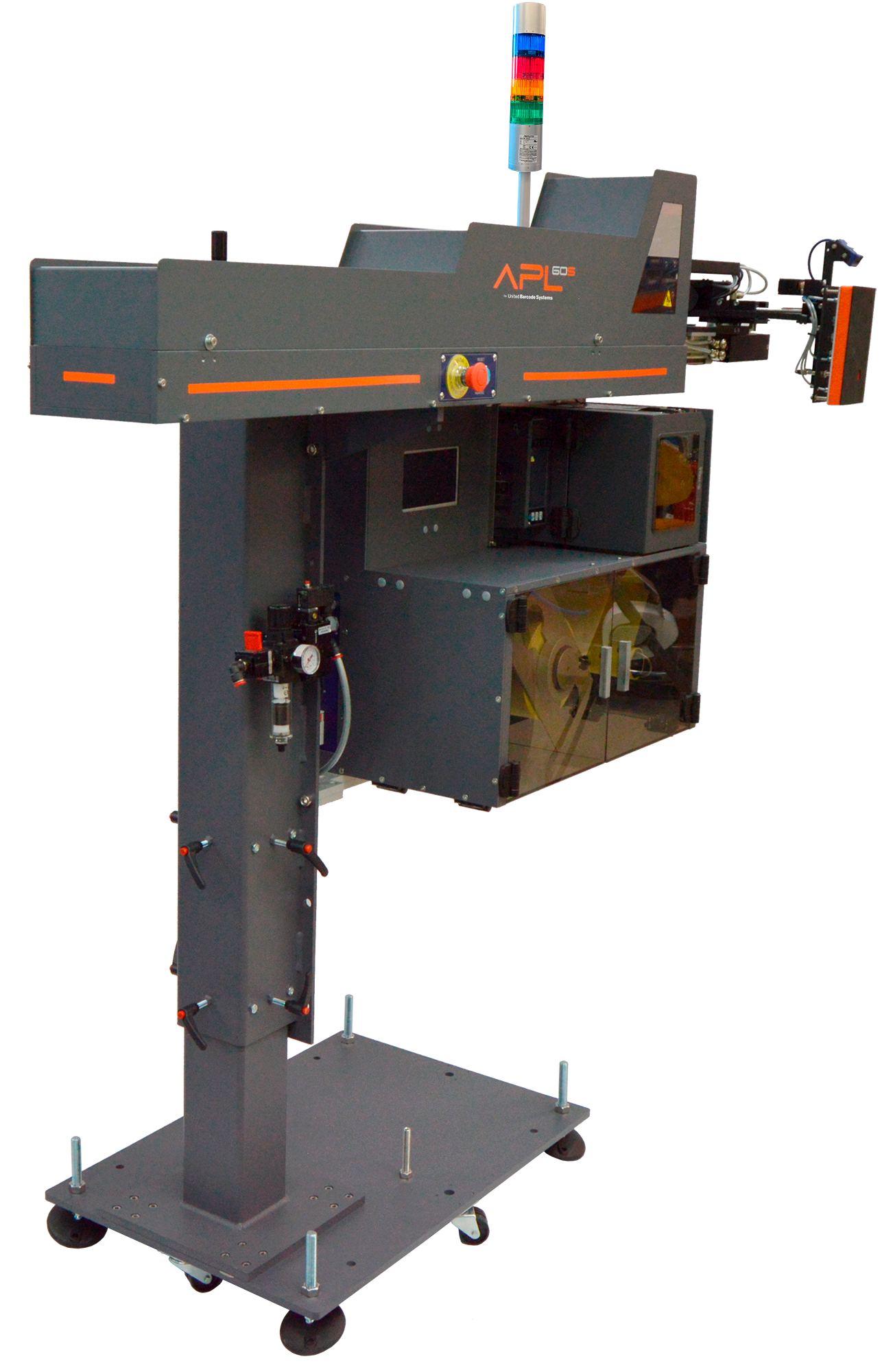

Pallet Print & Apply Systems

APL 60 Series

New Automatic Print & Apply labeling system for pallets for two sides. Manufactured to meet GS1 global standards of codification and traceability.

PALLET LABELING FOR MEDIUM AND HIGH VOLUME PRODUCTION PLANTS

- Configurable for printing and applying the label with variable data, in real time and automatically to 1 or 2 sides of the pallet.

- Manufactured to meet GS1 International global coding and traceability standards for pallet labeling with GS1-128 barcodes.

- Compact equipment, which has been developed for easy integration into end-of-line.

- Fully compatible with any OEM print engine in the market.

- 7" HMI display with user-friendly graphical interface to control all equipment parameters, showing real time information of the labeling process.

- Controlled by a PLC, easily adaptable to different working elements and equipment.

- Speed up to 180 pallets/hour with double label application.

*Depends on line speed and integration, type and number of labels applied.

- Smart labeling:

· Label presence sensor.

· Tamp-pad adaptable to irregular surfaces.

· Applied label detector. - Its barcode verifier/checker makes it possible to know if the code printing has been correct.

- Its light and acoustic beacon allows to know the status of the equipment and detect possible stoppages or incidents.

- High connection with any ERP, MES, WMS, DBMS, etc. system.

- Easy to integrate, it offers a wide capacity of connection to any information or automation system.

- Telescopic support adjustable in height using a spindle.

- Easy access to consumables.

Smart Labeling.

Automatic printing and application of labels with real time variable data. Integrated barcode verifier.

Labeling on 1 side of the pallet at high-speed.

Speed up to 10 pallets/minute.

Labeling up to 2 sides of the pallet complying with GS1 standards.

Speed up to 3 pallets/minute.

Do you need a compact machine for medium and high volume plants which labels up to 2 sides per pallet?

MANAGEMENT AND CONTROL OF THE LABELING SYSTEM WITH: UBS LABMAN

At United Barcode Systems we have developed the software for the management and control of all the labeling equipment of the production line.

- Automatic: The production line communicates with UBS LABMAN to indicate the product to be printed. No human intervention.

- Reprinting: Possibility to reprint the pallet label.

- Generation of pallet license plates (SSCC): 18 digits.

- Monitoring: Of all the equipment of the line, showing the status of each one of them.

- Instant communication: With the equipment of the production line, obtaining information in real time.

Which equipment is best suited to my needs?

.jpg)

equipos-etiquetado-palets-dos-lados.jpg)

etiquetado-final-linea-palet.jpg)

pallet-labeling-equipment-apl-60-series.jpg)

UBSLABMAN-software-gestion-equipos-codificacion_apl60S.jpg)

Línea-producción.3.jpg)